FDS Lean Production Scheduling & Execution

True visibility on Order completion status in face of uncertainties related to availability of machine and common parts.

Features of FDS’s LPSE

-

The perfect fit for the requirement of mass customization

-

Keep inventory at optimum levels, keeping the costs in check without compromising production rates and smooth operations

-

Material allocation and reallocation made easy! Calculations are done by the system and not manually by humans.

-

Use of latest technology allows complex functionality to be built and executed in no time

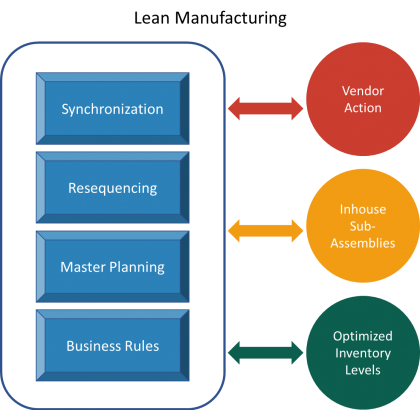

Lean Manufacturing

- High volume productions benefit significantly by embracing lean practices.

- Lean manufacturing allows segmenting production into balanced lines.

- It helps in increasing productivity and ensuring efficient delivery.

Modern Challenges in High-Volume Productions

- High volume manufacturing has moved from mass production to mass customization.

- High volume does not necessarily mean low variety.

- Customers want to know the status of their customized product

Manufacturing Companies’ Objectives

- Cater to increasing flexibility needs of the customer.

- Run the production lines smoothly with optimum inventory, despite large variety of subcomponents.

- Juggle between order-based-planning which is essential for on-time delivery to customer and part-based lean production lines in Lean Manufacturing

Limitations of the Planning Systems

- Many available planning and scheduling software work in only planning mode and eventually thrust execution on the shop floor personnel.

- These order-based APS systems cannot provide the visibility and quick re-sequencing that the lean production lines need.

- Order based systems fail to construct detailed part level scenarios on a minute-to-minute basis which are important for ensuring an uninterrupted flow line.