FDS Production Scheduler

FDS is one of the pioneers in Finite Capacity Scheduling , since 1988

Sharpen your decision-making ability and improve the competitive advantage in the market place with FDS Production Scheduler

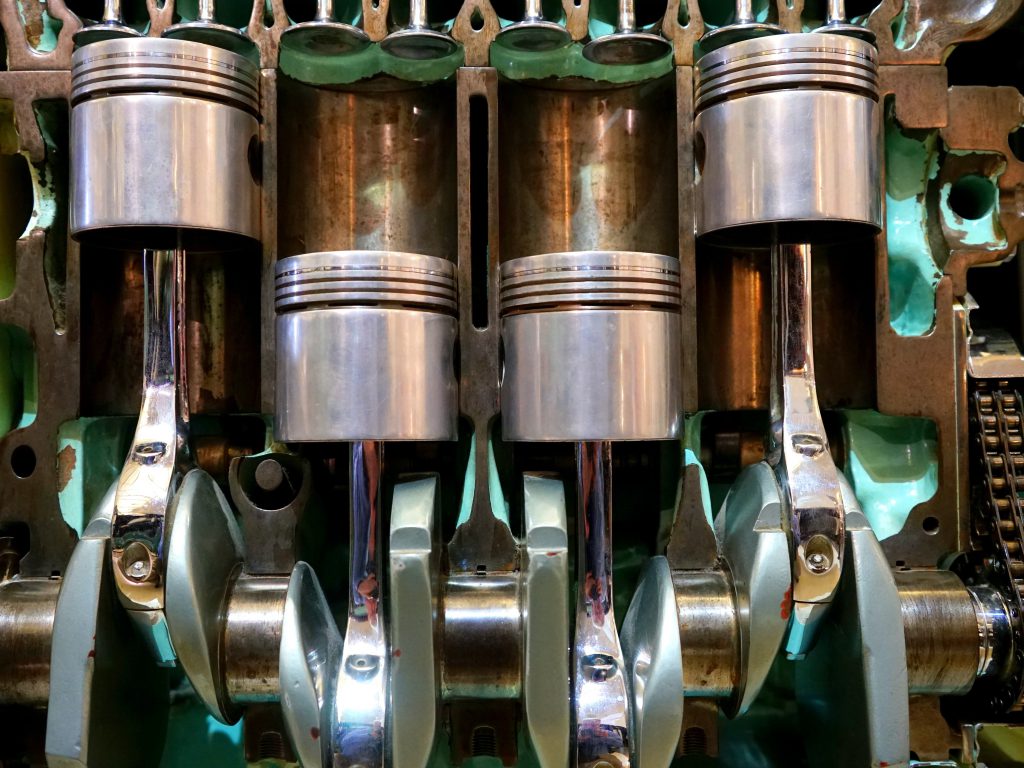

Multi-constraint scheduling system

A good fit for a variety of types of production

Perfect for handling of Scheduling assignments in Mould/Die Shops, Press Shops, Machinery Manufacturers (Boilers, Machine Tools, Engines) and general-purpose Machine Shops

Why FDS Shopfloor Scheduler?

- Helps you to plan your shop floor capacities proactively.

- Can simultaneously consider a host of resource constraints and production environment factors

- Shows potential bottlenecks before they confront you

- Saves Costs, Optimizes Resources

- Helps improve your due date performance

- Brings about better visibility on the shop floor

Experience the robustness and performance of FDS Production Scheduler

Bridge the gap

Close the gap across high-level plans and shop floor capabilities and constraints

Capacity-To-Plan

Build greater visibility for weeks into the future by generating realistic schedules

What-if Simulation

Experience the pack of powerful scheduling, modeling, ‘What if’ scenarios and shop floor update capabilities. Zero in on the best possible alternative with the What-if capability.

Integrate Or Use Standalone

Use as a stand-alone product or integrate with ERP and other systems. It’s easy to use, highly configurable, doesn’t need customization.

A System In Itself

It can double up as your Production Management System and in “Made-to-order’ businesses obviates the need for a conventional ERP system

Enjoy the benefits of FDS Shopfloor Scheduler

- Increase overall shop floor efficiency and throughput while finished good inventory is reduced.

- Harness your real production capacity to increase output.

- Give realistic delivery commitments.

- Carry out ‘What If ‘analysis prior to buying resources and thus reduce capital expenditure.

- Cut WIP, outsourcing and logistics costs.